OPERATION SYSTEM STOPWATCH WITH LAPTIMES

By

using Silicon Lab Toolstick850, a stopwatch is a handheld timepiece designed to

measure the amount of time elapsed from a particular time when activated to

when the piece is deactivated. A large digital version of a stopwatch designed

for viewing at a distance, as in a sports stadium, is called a stop clock.

The timing functions are traditionally

controlled by two buttons on the case. Pressing the top button starts the timer

running, and pressing the button a second time stops it, leaving the elapsed

time displayed. A press of the second button then resets the stopwatch to zero.

The second button is also used to record split times or lap times. When the

split time button is pressed while the watch is running, the display freezes,

allowing the elapsed time to that point to be read, but the watch mechanism

continues running to record total elapsed time. Pressing the split button a

second time allows the watch to resume display of total time. Mechanical

stopwatches are powered by a main spring, which must be periodically wound up

by turning the knurled knob at the top of the watch.

Digital electronic stopwatches are

available which, due to their crystal oscillator timing element, are much more

accurate than mechanical timepieces. In case, silicon lab toolstick850 already

have in toolstick850. Because they contain a microchip, they often include date

and time-of-day functions as well. Some may have a connector for external

sensors, allowing the stopwatch to be triggered by external events, thus

measuring elapsed time far more accurately than is possible by pressing the

buttons with one's finger. The device is used when time periods must be

measured precisely and with a minimum of complications. Laboratory experiments

and sporting events like sprints are good examples.

OBJECTIVE PROJECT

- To appreciate the hardware and software interfacing of a microcontroller system.

-

To design, write and test an assembly programming which meets a technical specification in a given target system.· To investigate how to use silicon lab Toolstick850.· To demonstrate the project how it works and build a fully functional stopwatch.· To train and create a new project from the hardware and simplicity studio software.

FLOWCHART

|

Process

of program stopwatch

|

SOFTWARE FUNCTIONAL

BLOCK DIAGRAM

ANALYSIS

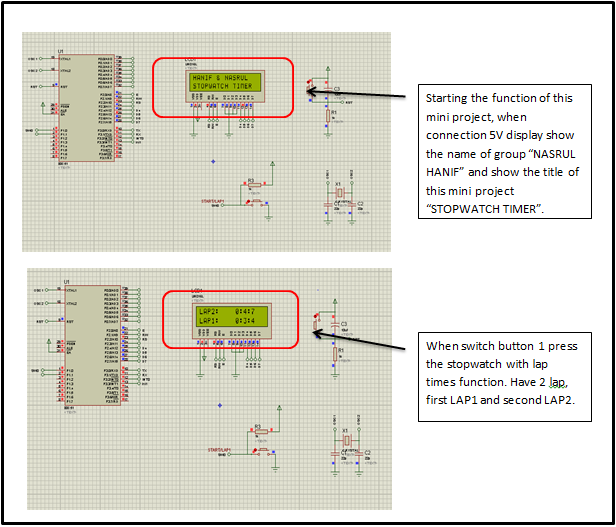

From the mini project, use PROTEUS to create a

circuit of this mini project “STOPWATCH WITH LAP TIMES” and create coding using

KEIL and run with Simplicity studio to run and burn the program C. Firstly, the

circuit always have some basic error because got a little mistake when solder

it. We use a Toolstick850 replace IC8051 because this Toolstick850 is easy then

IC8051. Stopwatch basically plays with time minutes, second and miliseconds so

the time should be running accurate. We got some error from a conversion

programmer from KEIL to SIMPLICITY STUDIO, stand still we change some

instructions on coding C. Basically, the 2 x 16 LCD works on 4-bit or 8-bit

data line and three control lines. Now we use LCD for 4-bit because it’s easy

to check the error. The control lines are RS, R/W and E. All communication

between 2 x 16 LCD and host processor is synchronized by E line. For this

Toolstick850 we change the connection port. Port LCD we use P0.0 to P0.7 in

Toolstick850. The output can be in result as we keep this program.

CONCLUSION

The

STOPWATCH has been using a system of "Proteus VSM software" to get

the schematic diagram. Use code on Keil software uVision4 and Simplicity

Studio. In addition, developing a code by using the output of 2x16 LCD unit

using ic8051 develop tools for measuring analog equipment. STOPWATCH time

tracking system for a setting that is programmed using coding C system. This

STOPWATCH has been set to two rounds of LAB at coding and displayed by the LCD

display. Each connection appearing in the circuit by using strips board because

it is easier to identify the error that will occur. For STOPWATCH can learn how

it works by using a microcontroller program.

REFERENCE

IV.

Note and refer From lecture ZULKHAIRI BIN MD

YUSOF